Pure Air

-

Location

3750 NW 28th St Bay 206 Miami FL 33142

Location

3750 NW 28th St Bay 206 Miami FL 33142

-

Email

Email

Location

3750 NW 28th St Bay 206 Miami FL 33142

Location

3750 NW 28th St Bay 206 Miami FL 33142

Email

Email

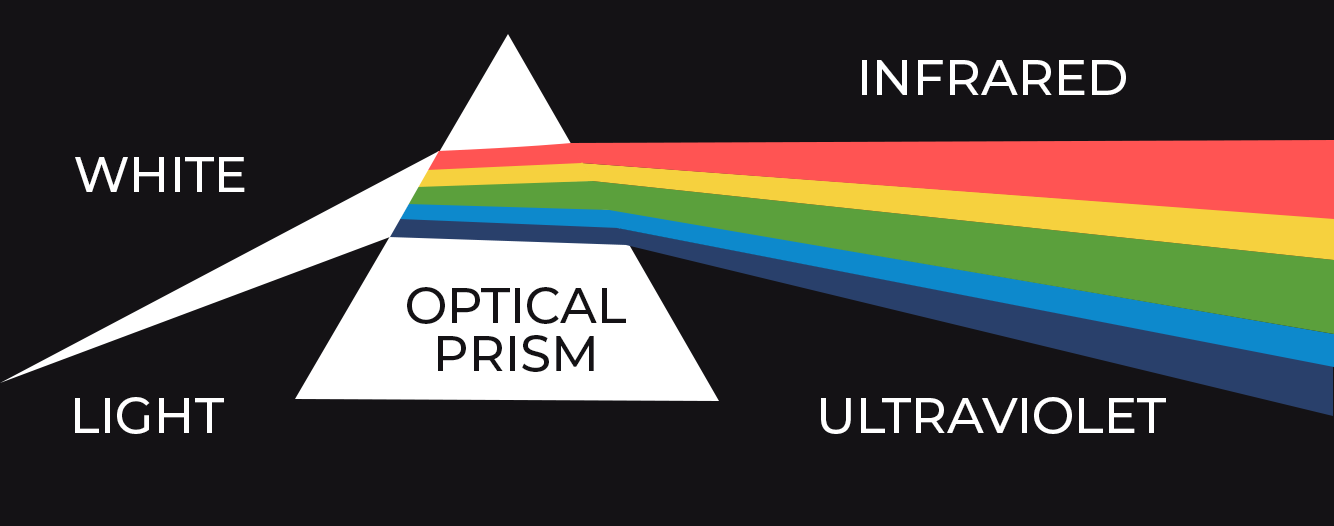

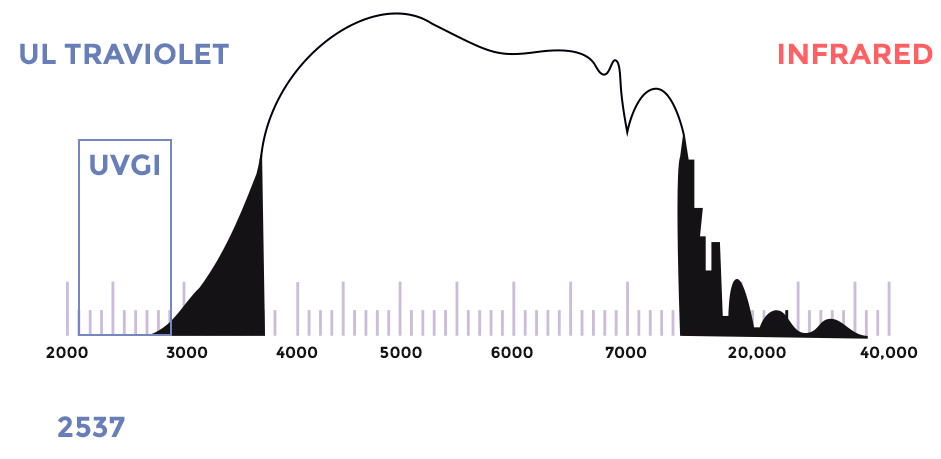

Ultraviolet Germicidal Irradiation The use of ultraviolet germicidal irradiation (UVGI) for the sterilization of microorganisms has been studied since the 1930s. Microbes are uniquely vulnerable to the effects of light at wavelengths at or near 2537 Angstroms due to the resonance of this wavelength with molecular structures. Looking at it another way, a quanta of energy of ultraviolet light possesses just the right amount of energy to break organic molecular bonds. This bond breakage translates into cellular or genetic damage for microorganisms. The same damage occur to humans, but is limited to the skin and eyes.

The ultraviolet component of sunlight is the main reason microbes die in the outdoor air. The die-off rate in the outdoors varies from one pathogen to another, but can be anywhere from a few seconds to a few minutes for a 90-99% kill of viruses or contagious bacteria. Spores, and some environmental bacteria, tend to be resistant and can survive much longer exposures. UVGI systems typically use much more concentrated levels of ultraviolet energy than are found in sunlight.

Some properly designed, and well-maintained, UVGI installations have proven highly effective, as in certain hospital, and some studies performed in schools. CDC guidelines recommend the use of UVGI only with the simultaneous of HEPA filters and high rates of purge airflow. The germicidal effects can also be species-dependent.

Laboratory tests have achieved extremely high rates of mortality under idealized conditions. In actual application, many factors can alter the effectiveness of UVGI, including the following: Exposure time (the air velocity must allow for a sufficient dose). Room air mixing (for non-powered applications like ceiling units). Power levels. The presence of moisture or particulates provide protection for microbes. Dust settling on the light bulbs can reduce exposures, maintenance is necessary.

One especially effective application of UVGI is the control of microbial growth in air handling unit cooling coil and filter assemblies. The constant exposure had been found to be very effective at controlling fungal growth, either because the spores are inactivated, orperhaps because mycelial growth cannot be sustained under continuous exposure.

Certain types of UVGI designs seem to provide a much higher rate of disinfection than standard models operating at nearly identicalspectrums, the difference being the result of improvements in the electrical power controls and regulation of internalplasma temperature, resulting in the generation of a more constant density at a distance from the light source.

Viruses are especially susceptible to UVGI, more so than bacteria, but are also very difficult to tilter. Some studies have shown that viruses are more sensitive to ultraviolet radiation at wavelengths somewhat above the normal UVGI broad-band wavelength of 2537 A (Rauth 1965;Setlow 1961). A combination of filtration for bacteria and spores, with UVGI for viruses may be an optimum combination if all components are sized appropriately.

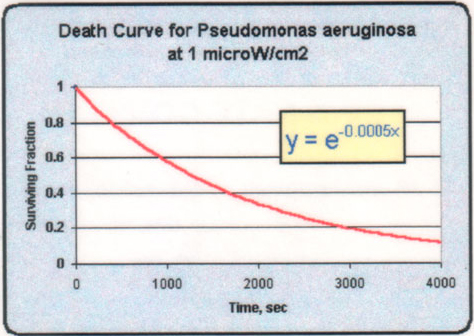

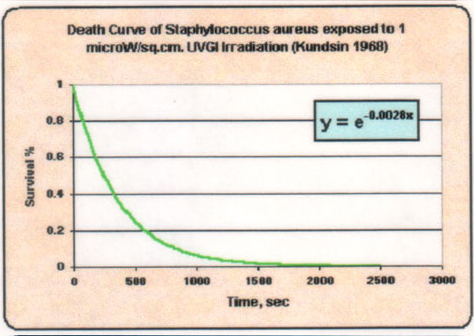

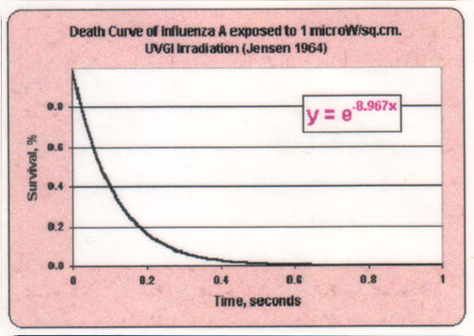

UVGI inactivates pathogens according to the standard decay equation

S = exp(-kt)

In this equation S represents the fraction of the original population that survives exposure at time t. The rate constant, k, has the units of 1/s, and in the example death curve for Pseudomonas aeruginosa shown below, the rate constant has a value of 0.0005 1/s. The energy level for this example is 1 microwatt/sq.cm. Modern UVGI units typically put out between 25 and 150 microwatts per sq. cm.

At the right are some typical inactivation curves, for Pseudomonas aeruginosa, Staphylococcus aureus, and the Influenza A virus. These curves illustrate the effects of UVGI irradiation at the comparatively low ‘baseline’ energy level of 1 microwatt/sq.cm. The inactivation curve of these microbes at an energy level of 25 microwatts could be obtained by multiplying the rate constant shown in each respective equation on the charts, by 25.

In the chart equations, the “x” represents the time, t, in seconds. The data plotted in these charts represents a logarithmic curve fitted to the data provided by the indicated reference.

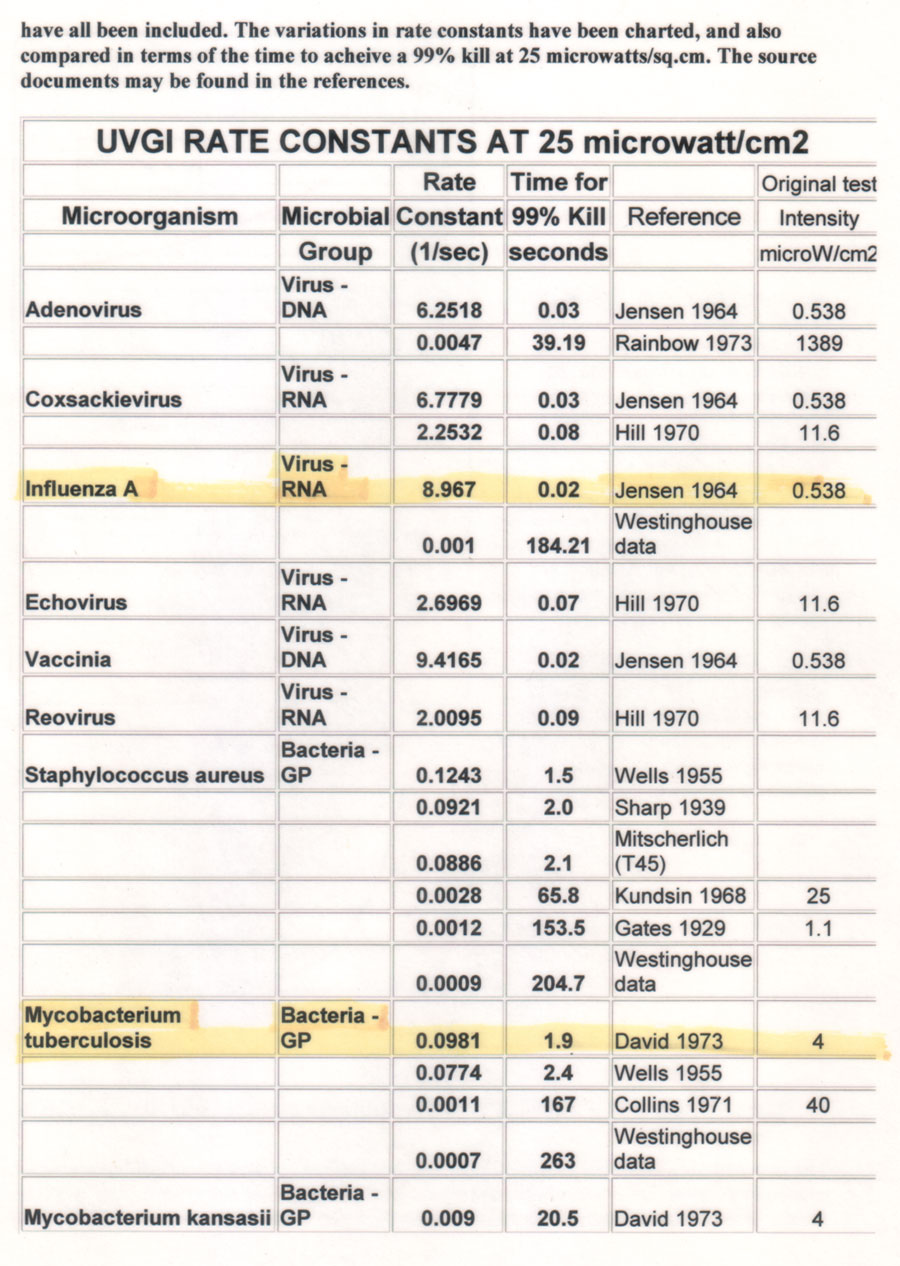

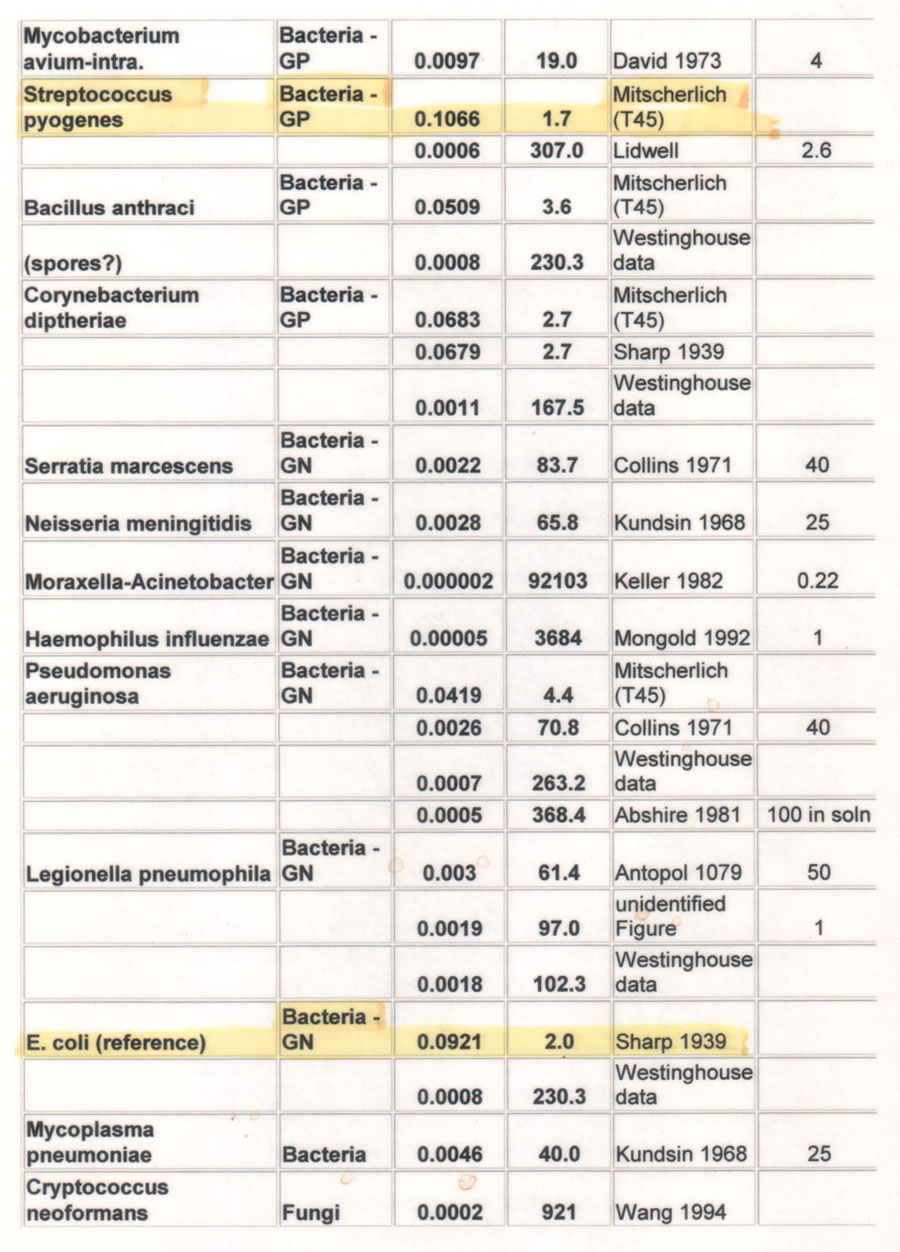

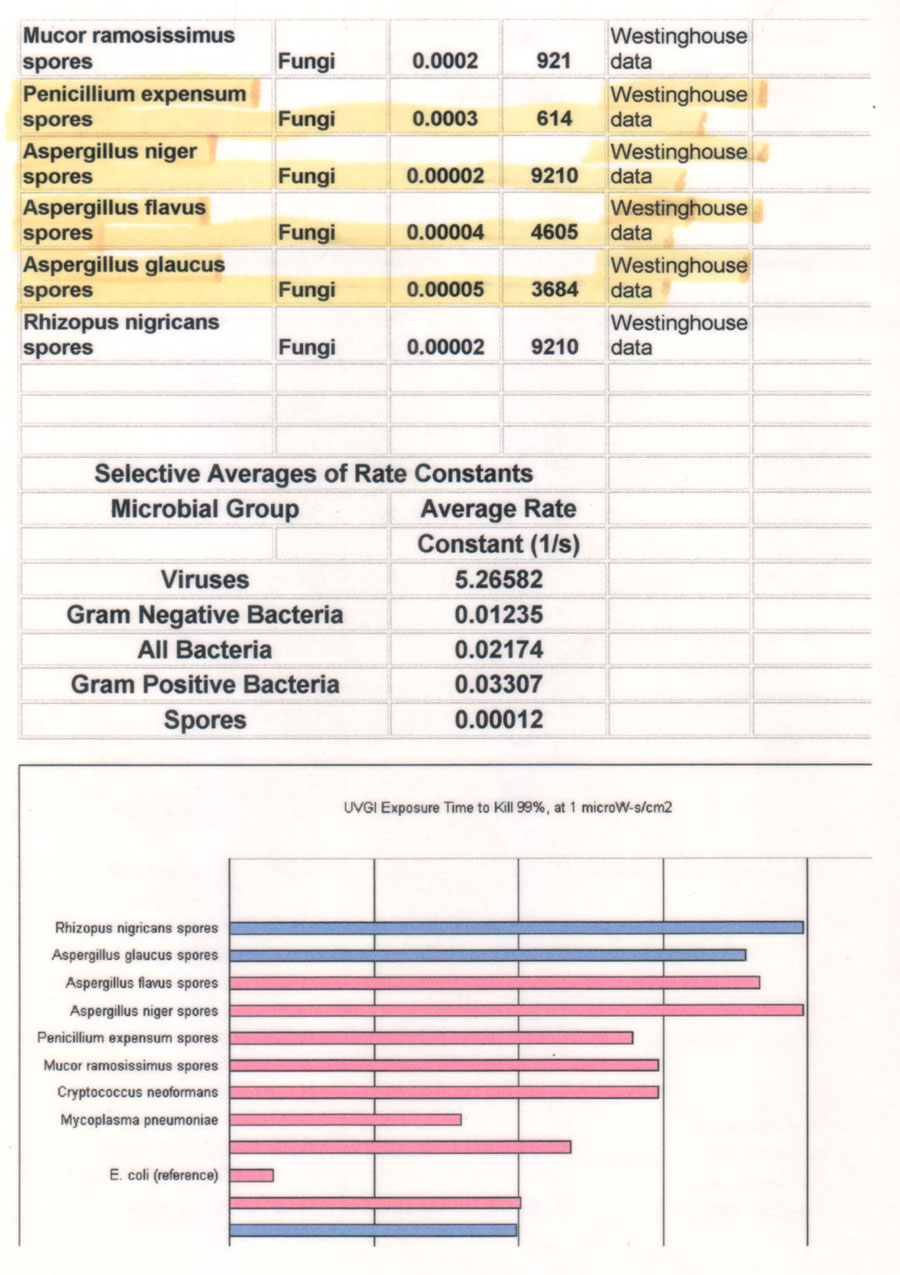

The rate constant k has been determined experimentally for a number of bacteria, viruses and spores, at different power levels. Summarized below are many of the known reate constants for the indicated pathogens. Since many researchers have obtained values that differ, they have been included. The variations in rate constants have been charted, and also compared in terms of the time to achieve a 99% kill at 25 microwatts/sq.cm. The source documents may be found in the references.